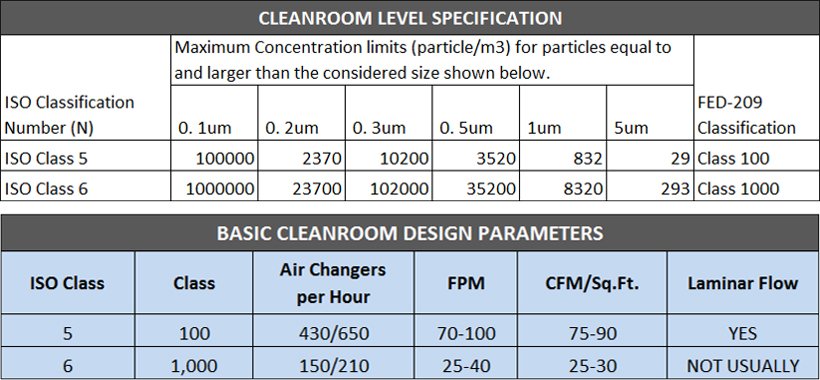

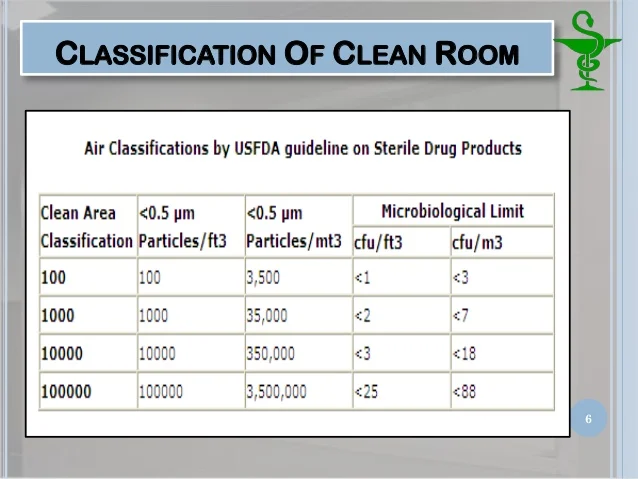

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area. Cleanrooms are rated based on the number of particles they can handle.

Clean Rooms Specifications And Design Heser Vtngcf Org

The purpose of this guideline is to provide design and construction suggestions for cleanrooms housing bio pharmaceutical processes.

Clean room design standards. General service administrations standards known as fs209e were applied virtually worldwide. Iso 14644 1 and standard 209e standards. A clean room gmp cleanroom in my mind are a combination of engineering design fabrication finish and operational controls control strategy that are required to convert a normal room to a clean room.

Basic clean room requirements designs for gmp clean rooms what is a clean room. They should be computed by an hvac cleanroom expert as many aspects must be taken into consideration such as the size of the room the number of people in the room the equipment in the room the processes involved the heat gain etc. For those companies that need to adhere to specific design standards they must understand that clean rooms can be built and operated to meet different cleanliness classifications depending on the environmental conditions required for their use.

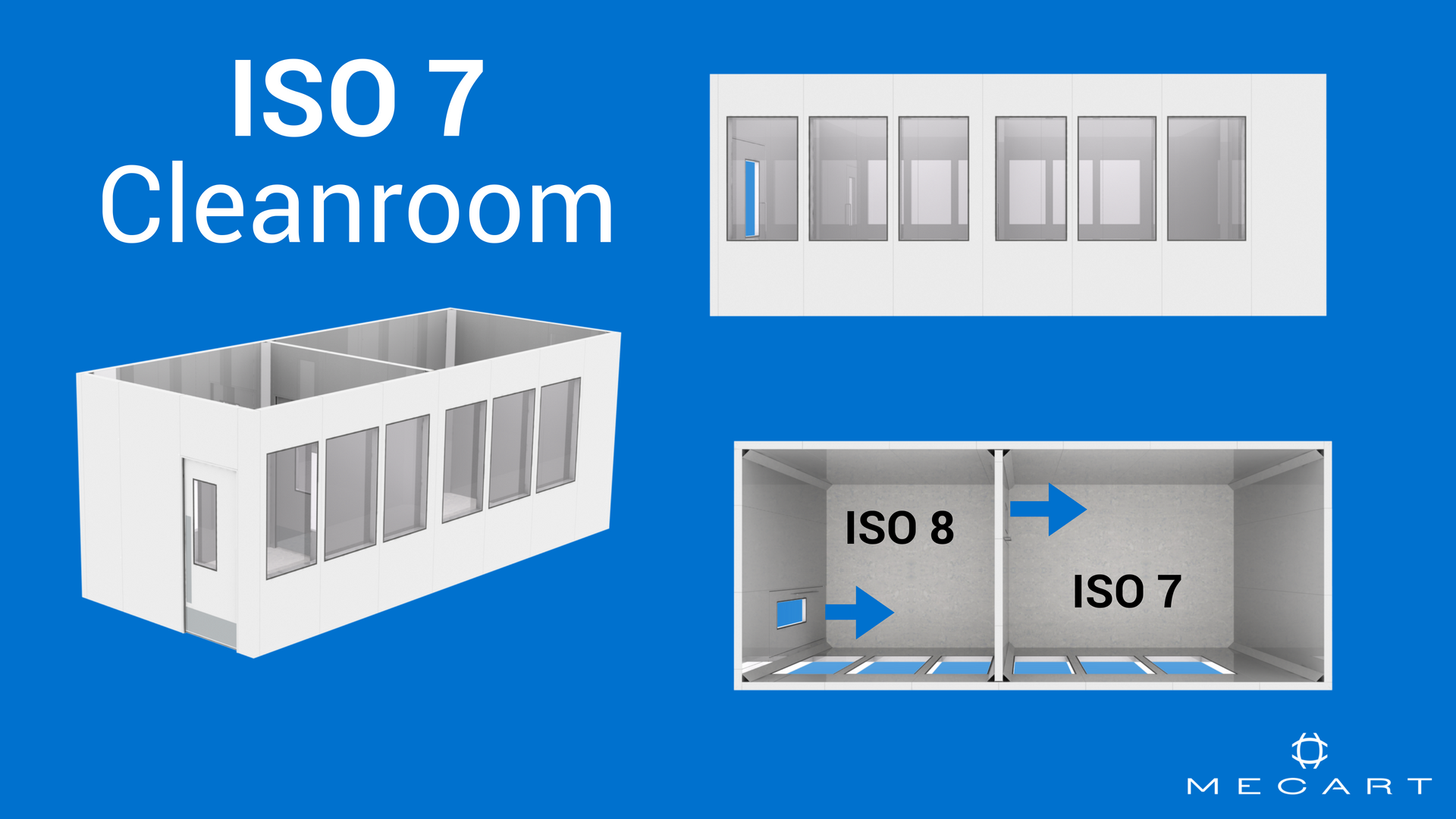

Before global cleanroom classifications and standards were adopted by the international standards organization iso the us. Ordinary room air is approximately class 1000000 or iso 9. They range from an iso class 1 cleanest to an iso class 8 least clean.

Ashrae design guide for cleanrooms. There are two standards that our users typically refer to. The old fs209e standard which contained six classes and the international replacement iso 14644 1 classification system which adds two cleaner standards and one dirtier standard fs209e cleanroom classifications were rated according to how much particulate of specific sizes exist per cubic foot see chart below.

Both standards classify a cleanroom by the number of particles found in the laboratorys air. It offers an approachable technical perspective to designers builders owners and operators of cleanrooms. Click the photo above to enlarge.

Cleanrooms are designed to maintain extremely low levels of particulates such as dust airborne organisms or vaporized particles. The ashrae design guide for cleanrooms offers a practical comprehensive approach to cleanroom theories fundamentals performance control testing and industrial applications. A cleanroom or clean room is a facility ordinarily utilized as a part of specialized industrial production or scientific research including the manufacture of pharmaceutical items integrated circuits crt lcd oled and microled displays.

Clean room design standards. The above suggested air changes per hour are only a design rule of thumb. Cleanroom requirements and standards provide a direct and easy to understand way of detailing the differences between the eight classes of cleanrooms.

The following suggestions are intended to assume that the facilities when used properly will meet the airborne particulate classes for cleanrooms and clean zones and will provide an environment that does not negatively affect bio pharmaceutical.

Hvac Cleanroom Design Concepts For Pharmaceutical Compounding

What Is A Cleanroom Cleanroom Classifications Class 1 10 100

Cleanroom Classifications Iso 8 Iso 7 Iso 6 Iso 5

Clean Room Installation What Is A Clean Room

5 Questions To Consider When Designing A Cleanroom

Hydroflex Group Purmop And 2 0 Ergo Touch Free Cleanroom Mops

Clearsphere Cleanroom Solutions Design And Installation

What Is A Cleanroom Cleanroom Classifications Class 1 10 100

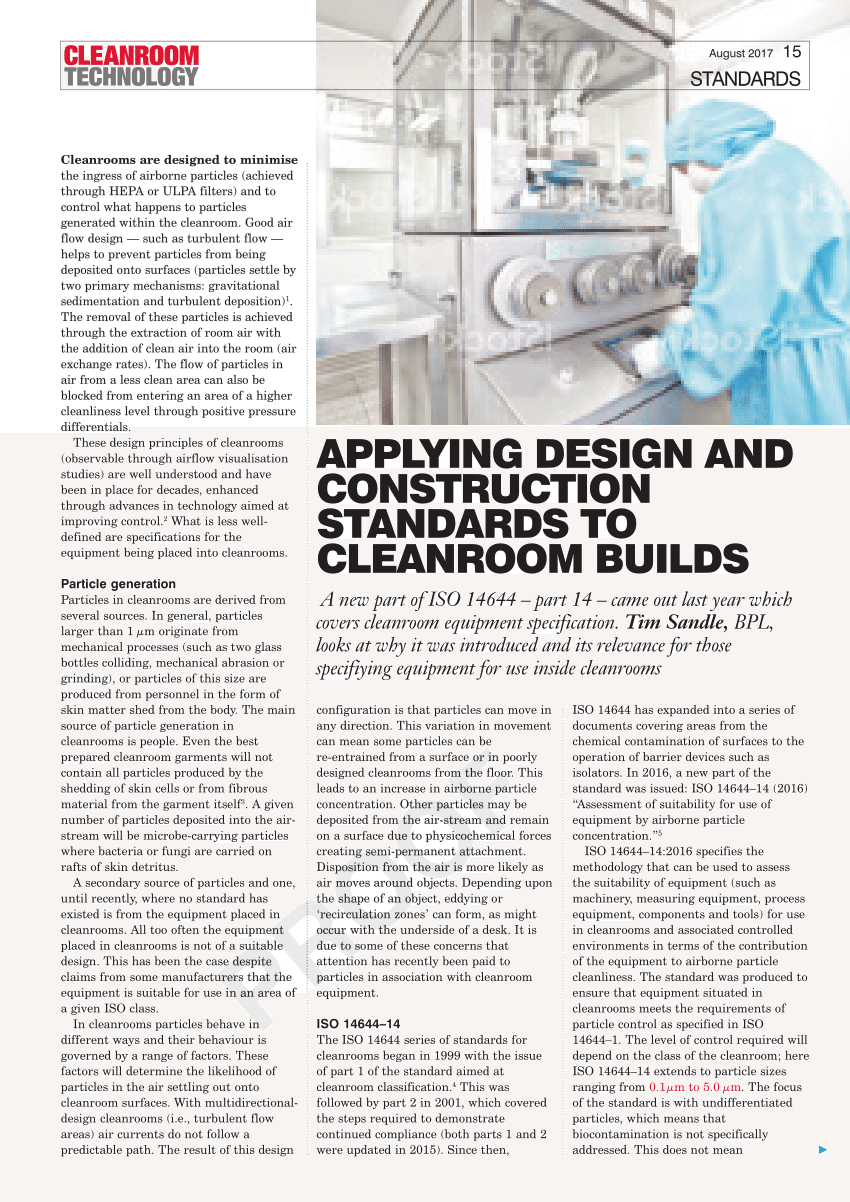

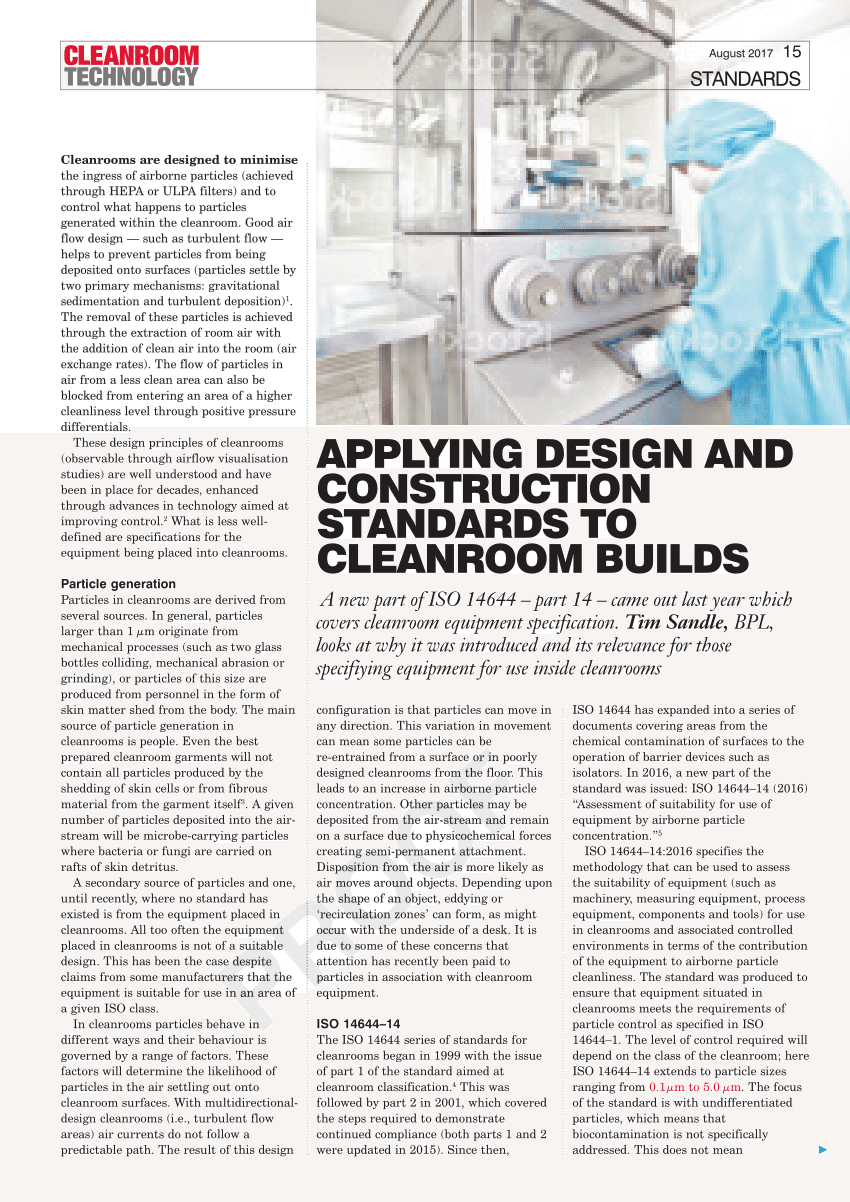

Pdf Applying Design And Construction Standards To Cleanroom Builds

Usp 797 Clean Room Guidelines Standards For Sterile Compounding Labs

Clean Room Classifications And Iso Standards Cleanroom Requirements

Robin Sanat Hounam Cleanroom Design Hvac Test Validation

Cleanroom Classifications Iso 8 Iso 7 Iso 6 Iso 5

What Is A Cleanroom Cleanroom Classifications Class 1 10 100

Cleanroom Cleaning And Gowning Protocol Guide Iso 14644

Clean Room Design Consultants Iso 14644

What Is A Cleanroom Angstrom Technology

Cleanroom Classifications Iso 8 Iso 7 Iso 6 Iso 5

Pharmaceutical Clean Room Classification

Low Cost Automation Tutorial March 2012 Archives

Modern Cleanroom Industry Standards Therma

Cleanroom Design In 10 Easy Steps

No comments:

Post a Comment